ENGINE PLANT

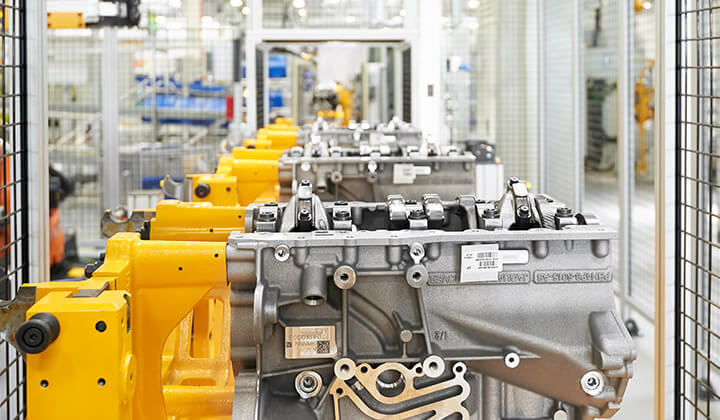

In July 2017, Chery Jaguar Land Rover Engine Plant, Jaguar Land Rover's first overseas engine plant, was completed and open, achieving the machining capacity of 180,000 units, and the assembly capacity of 240,000 units.

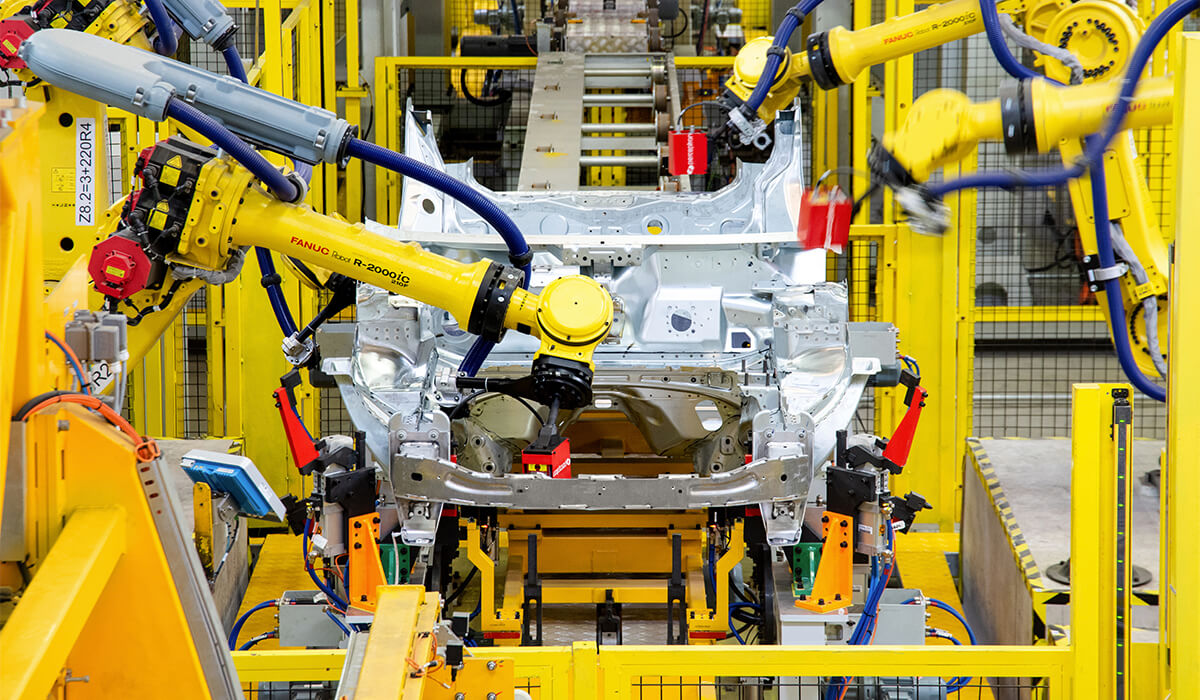

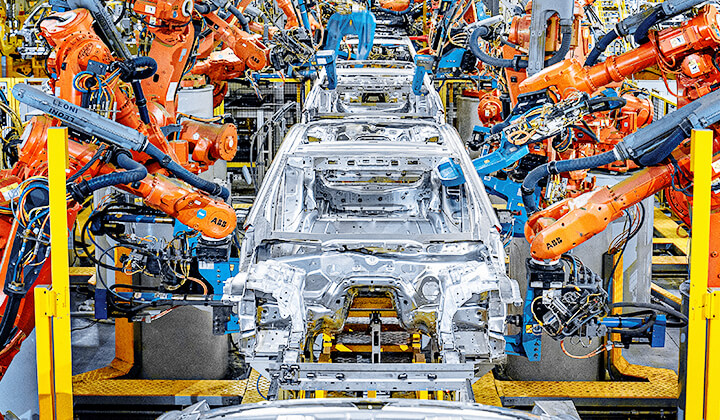

With intelligent, environmental friendly and high efficiency, engine plant introduced the latest and advanced Jaguar Land Rover powertrain technology and manufactured ingenium engine family, which marks Chery Jaguar Land Rover's continuous strengthening of "intelligence" to drive the future efficiently.

Ingenium engine family is the advanced engine family independently developed by Jaguar Land Rover in its history and also the core of Jaguar Land Rover's low emission powertrain strategy. The Ingenium 2.0L four cylinder engine was awarded as Top 10 Ward Engine in 2018 due to its strong power, outstanding fuel economy and multiple innovations.